Introduction

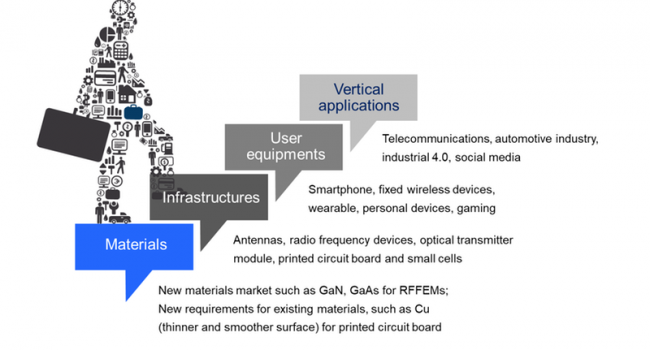

5G communication technology promises significant advancements, such as faster speed, lower latency, improved connection density and wider coverage; thus enabling implementation of Internet of Things (IoT), augmented reality (AR) or virtual reality (VR) applications, factory automation, vehicular communications and other applications where security, reliability, quality of service and efficiency are critical. While the lucrative 5G industry is preparing businesses to experience digital transformation, electronic manufacturers behind the scenes are at the forefront of developing high performance components to support reliable implementation. Major challenges to be addressed by electronic manufacturers include managing extreme thermal conditions within increasing smaller encapsulated components and delivering high performance at low power. These challenges can be overcome through the use of high-performance materials [1].