INTRODUCTION

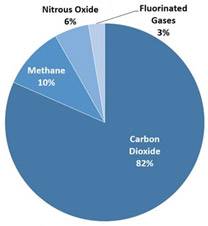

Fast-paced industrialization, accompanied by the indiscriminate burning of fossil fuels, has led to excessive emission of greenhouse gases over the past two centuries, resulting in the global warming being witnessed today[1]. According to the U.S. Environmental Protection Agency (USEPA), the total emission of greenhouse gases in the US alone during the year 2017 was 6,457 Million Metric Tons of Carbon di oxide (CO2) equivalent, as shown in Figure 1. As per the Intergovernmental Panel on Climate Change (IPCC), such emissions have to be reduced by 50 to 80% by the year 2050[2].

In 2019, Saudi Aramco developed the Converge Polyol technology to produce high-performance polyols wherein waste CO2 combines with hydrocarbon feedstock. Propylene oxide, on polymerization in the presence of a proprietary catalyst, produces 100% polypropylene carbonate (PPC), and the resultant polyols are found to have perfect repeating units. The applications of the Converge polyol technology include coatings, adhesives, sealants and elastomers. Converge polyols impart improved abrasion and environmental resistance on coatings, improve bond strength in adhesives, enhance tensile and tear properties when added to elastomers, produce nontoxic by-products in electronic and ceramic industries, and improve both durability and compressive strength in composites51.

In 2019, Saudi Aramco developed the Converge Polyol technology to produce high-performance polyols wherein waste CO2 combines with hydrocarbon feedstock. Propylene oxide, on polymerization in the presence of a proprietary catalyst, produces 100% polypropylene carbonate (PPC), and the resultant polyols are found to have perfect repeating units. The applications of the Converge polyol technology include coatings, adhesives, sealants and elastomers. Converge polyols impart improved abrasion and environmental resistance on coatings, improve bond strength in adhesives, enhance tensile and tear properties when added to elastomers, produce nontoxic by-products in electronic and ceramic industries, and improve both durability and compressive strength in composites51. In partnership with Calix, an Australian technology company, and a European consortium, Heidelberg cement has planned to build an extension of their LEILAC 1 (Low Emissions Intensity Lime and Cement) technology, named LEILAC 2, for carbon capture at its cement plant in Hanover, Germany. The project is based on Calix’s “calciner technology” and is expected to cost €25 million ($34.2 million U.S.). The goal is to capture 20% of the cement plant’s capacity, or 100,000 tons of CO2 per year. The project is expected to be in operation by 202552.

In partnership with Calix, an Australian technology company, and a European consortium, Heidelberg cement has planned to build an extension of their LEILAC 1 (Low Emissions Intensity Lime and Cement) technology, named LEILAC 2, for carbon capture at its cement plant in Hanover, Germany. The project is based on Calix’s “calciner technology” and is expected to cost €25 million ($34.2 million U.S.). The goal is to capture 20% of the cement plant’s capacity, or 100,000 tons of CO2 per year. The project is expected to be in operation by 202552. Lotte Chemical of South Korea has started using CCU technology for converting CO2 to polycarbonate, a raw material for the production of dry ice and semiconductor cleaning liquid. The company uses Airrane’s gas separation membranes, which are very fine hollow fibers through which different mixtures of gases are fed in a process called selective permeation. It is an asymmetric filter made of various types of polymer53. Lotte Chemical aims to utilize more than 200,000 tons of CO2 annually by expanding related facilities.

Lotte Chemical of South Korea has started using CCU technology for converting CO2 to polycarbonate, a raw material for the production of dry ice and semiconductor cleaning liquid. The company uses Airrane’s gas separation membranes, which are very fine hollow fibers through which different mixtures of gases are fed in a process called selective permeation. It is an asymmetric filter made of various types of polymer53. Lotte Chemical aims to utilize more than 200,000 tons of CO2 annually by expanding related facilities. Piñon Midstream has launched its Greenfield Dark Horse Sour Gas Treating and Carbon Capture Facility with an acid gas sequestration well, which will remove both CO2 and hydrogen sulfide (H2S) from the incoming natural gas stream. The pipeline construction is under progress in Lea County, New Mexico. The project has the capability of treating up to 400 million cubic feet of sour gas per day54.

Piñon Midstream has launched its Greenfield Dark Horse Sour Gas Treating and Carbon Capture Facility with an acid gas sequestration well, which will remove both CO2 and hydrogen sulfide (H2S) from the incoming natural gas stream. The pipeline construction is under progress in Lea County, New Mexico. The project has the capability of treating up to 400 million cubic feet of sour gas per day54. Exxonmobil has planned to invest $3 billion further on some of its new ventures on carbon capture, or on the expansion of existing CCS projects, upto 2025. Some of the projects include installation of a CCS hub in Singapore, expansion of its La Barge CCS facilities in Wyoming, agreement on a joint project in Porthos (Port of Rotterdam CO2 Transportation Hub) for caputring industrial CO2 and transporting it to North Sea offshore gas fields etc55.

Exxonmobil has planned to invest $3 billion further on some of its new ventures on carbon capture, or on the expansion of existing CCS projects, upto 2025. Some of the projects include installation of a CCS hub in Singapore, expansion of its La Barge CCS facilities in Wyoming, agreement on a joint project in Porthos (Port of Rotterdam CO2 Transportation Hub) for caputring industrial CO2 and transporting it to North Sea offshore gas fields etc55. Climeworks is a Swiss Company specializing in CO2 capture technology. Climework’s machines consist of modular CO₂ collectors that can be stacked to build machines of any size. The machines are powered solely with renewable energy or energy-from-waste. First, air is drawn into the collector with a fan. CO₂ is captured on the surface of a highly selective filter material that sits inside the collectors. Once the filter material is filled with CO₂, the collector is closed. The temperature is then increased between 80 and 100°C to release the CO₂. Finally, the high-purity, high-concentration CO₂ is collected. The filter can be reused many times and may last for several thousand cycles62.

Climeworks is a Swiss Company specializing in CO2 capture technology. Climework’s machines consist of modular CO₂ collectors that can be stacked to build machines of any size. The machines are powered solely with renewable energy or energy-from-waste. First, air is drawn into the collector with a fan. CO₂ is captured on the surface of a highly selective filter material that sits inside the collectors. Once the filter material is filled with CO₂, the collector is closed. The temperature is then increased between 80 and 100°C to release the CO₂. Finally, the high-purity, high-concentration CO₂ is collected. The filter can be reused many times and may last for several thousand cycles62. Solidia is a cement and concrete company having concrete curing technology with CO2 instead of water. The CO2 reacts with cement to make calcium carbonate and silica, which harden the structure to form concrete. Solidia’s technology has been found to be efficient for the removal of 1.5 gigatonnes of CO2 from atmosphere; which saves 3 trillion litres of fresh water, reduces energy consumption by 260 million oil barrels, and eliminates 100 million tonnes of concrete landfill 63, 64.

Solidia is a cement and concrete company having concrete curing technology with CO2 instead of water. The CO2 reacts with cement to make calcium carbonate and silica, which harden the structure to form concrete. Solidia’s technology has been found to be efficient for the removal of 1.5 gigatonnes of CO2 from atmosphere; which saves 3 trillion litres of fresh water, reduces energy consumption by 260 million oil barrels, and eliminates 100 million tonnes of concrete landfill 63, 64.

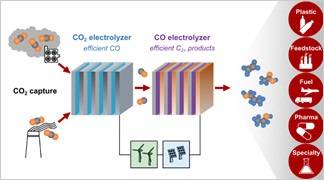

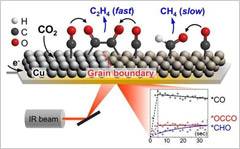

The goal of Lectrolyst is to convet CO2 and make valuable chemicals and fuels. With the help of tandem electro-chemical reactors, the scientists carried out a two-step process of transforming CO2 as shown in Figure 10 67, 68.

The goal of Lectrolyst is to convet CO2 and make valuable chemicals and fuels. With the help of tandem electro-chemical reactors, the scientists carried out a two-step process of transforming CO2 as shown in Figure 10 67, 68.